Plastic welding technology revolutionizes automotive restoration by seamlessly joining diverse plastic materials, enhancing structural integrity and aesthetic appeal with near-invisible bonds. Its adaptability, efficiency, and quality make it ideal for complex damage repairs, minimizing waste and turnaround times while catering to demanding customers seeking top-tier services.

Plastic welding technology is transforming the landscape of repairs, offering versatile solutions for diverse materials. Its significance is evident across industries, ensuring robust and durable repairs that mimic the original structure. This advanced technique addresses complex damage restoration, from automotive components to medical devices, providing efficient, cost-effective, and reliable alternatives. By leveraging plastic welding, professionals can achieve precise, high-quality outcomes, underscoring its essential role in modern repair practices.

- Versatility of Plastic Welding Technology

- Ensuring Quality and Durability in Repairs

- Efficient Solutions for Complex Damage Restoration

Versatility of Plastic Welding Technology

Plastic welding technology offers unparalleled versatility when it comes to repairs, especially in the realm of automotive restoration and classic car restoration projects. This innovative technique enables technicians to seamlessly join a wide array of plastic materials, making it an indispensable tool for achieving precise and durable repairs. Whether repairing cracks, joining components, or replacing parts in autobody repairs, plastic welding technology provides consistent and high-quality results.

Unlike traditional methods that may leave visible seams or require extensive sanding, modern plastic welding technology ensures near-invisible bonds. This not only enhances the aesthetic appeal of restored vehicles but also guarantees structural integrity. Moreover, its versatility allows for the adaptation to various plastic types commonly used in automotive manufacturing, making it a game-changer for those involved in meticulous and intricate repairs.

Ensuring Quality and Durability in Repairs

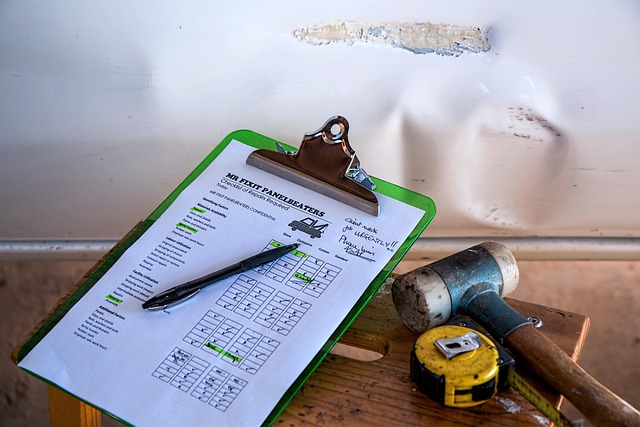

Ensuring quality and durability in repairs is paramount for any automotive service center. Plastic welding technology plays a pivotal role in achieving this goal, especially when addressing car collision repair or collision damage repair scenarios. By utilizing advanced plastic welding techniques, skilled technicians can expertly mend car body repairs, restoring them to near-original condition. This technology enables precise fusion of various plastic components found in modern vehicles, ensuring a strong and lasting bond.

Compared to traditional repair methods, plastic welding offers enhanced structural integrity for car body repair work. The process allows for minimal material wastage, preserving the vehicle’s original design and aesthetic appeal. Moreover, it facilitates quicker turnaround times without compromising on quality. This efficiency is particularly beneficial in busy workshops dealing with multiple collision damage repairs, ensuring clients receive their vehicles in a timely manner while maintaining high standards.

Efficient Solutions for Complex Damage Restoration

When it comes to complex damage restoration, plastic welding technology offers efficient and effective solutions. This innovative technique is particularly invaluable for repairing cars with minor scratches or dents, including bumper repairs. Traditional methods often leave visible traces, but modern plastic welding seamlessly integrates damaged areas, ensuring a flawless finish.

Body shops equipped with this technology can provide top-tier services, enhancing the overall aesthetic appeal of vehicles. By utilizing plastic welding, technicians can restore cars to their original condition, effectively erasing unsightly scratches and bumps, thus catering to customers seeking precise and comprehensive repairs for their vehicle’s exterior.

Plastic welding technology is a versatile and indispensable tool for achieving high-quality repairs, ensuring durability, and offering efficient solutions for complex damage restoration. Its precision and versatility make it a game-changer in various industries, allowing for robust and reliable fixes that match the original material’s performance. By embracing this technology, professionals can navigate intricate repair challenges, ultimately providing superior outcomes.