Plastic welding technology revolutionizes the automotive sector by facilitating lightweight vehicle construction, boosting fuel efficiency and environmental sustainability. Its versatility enables both manufacturing and repair, offering precise, specialized services that enhance structural integrity, aesthetic appeal, and cost-effectiveness compared to traditional metalworking methods. This technology empowers designers with flexibility for intricate geometric designs and lightweight materials, while allowing restoration experts to reproduce original parts accurately and minimize damage during repairs.

Plastic welding technology is revolutionizing vehicle performance by offering enhanced lightness, durability, and design flexibility. This innovative process allows for significant weight reduction, improving fuel efficiency and overall vehicle dynamics. Through advanced fusion techniques, plastic welding boosts longevity, ensuring cars withstand rigorous conditions. Moreover, it enables the creation of complex, lightweight components that enhance safety and contribute to more sustainable transportation. Discover how this technology is shaping the future of automotive manufacturing.

- Enhancing Lightness: Plastic Welding for Vehicle Weight Reduction

- Boosting Durability: Unlocking Longevity through Fusion Techniques

- Design Flexibility: How Welding Enables Innovative Car Parts

Enhancing Lightness: Plastic Welding for Vehicle Weight Reduction

Plastic welding technology plays a pivotal role in enhancing lightness and overall vehicle performance. By enabling the fusion of various plastic components, this innovative process allows automotive manufacturers to reduce the overall weight of vehicles significantly. Lighter vehicles translate into improved fuel efficiency, as less energy is required to propel them. This is especially crucial in today’s market where environmental considerations are at the forefront.

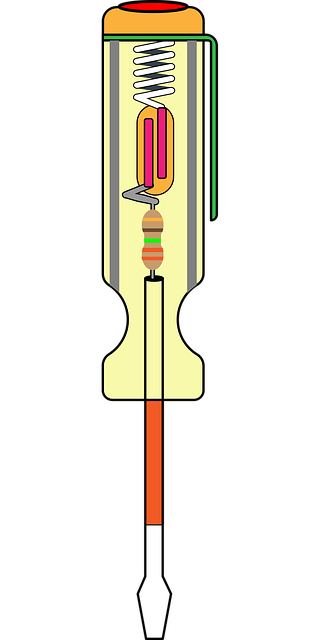

Moreover, plastic welding facilitates precise and efficient repairs, including those for vehicle body repair and auto repair near me services. Unlike traditional metal welding, plastic welding techniques can be applied to a wide range of materials commonly used in modern vehicles. This versatility makes it an indispensable tool for both manufacturers aiming to streamline production and local auto repair shops offering specialized services.

Boosting Durability: Unlocking Longevity through Fusion Techniques

Plastic welding technology plays a pivotal role in enhancing the durability of vehicles, extending their lifespan and reducing the need for frequent repairs. The fusion techniques employed in this process ensure that plastic components, which are increasingly common in modern automobiles due to their lightweight properties and cost-effectiveness, are joined together with precision and strength. This is particularly beneficial in collision repair services, where restoring a vehicle’s structural integrity is paramount.

By mastering the art of plastic welding, experts in Mercedes Benz collision repair and other automotive sectors can effectively mend and strengthen damaged panels, bumpers, and interior parts. This not only preserves the aesthetic appeal but also guarantees long-term performance, making vehicles more reliable and safer on the road. The advanced welding technology allows for intricate repairs, matching the original specifications of the vehicle, thereby providing an alternative to costly replacement parts in car dent repair scenarios.

Design Flexibility: How Welding Enables Innovative Car Parts

Plastic welding technology has revolutionized the automotive industry, offering unprecedented design flexibility for vehicle manufacturers and restorers. Traditional methods often relied on metal components, restricting designers to specific shapes and structures. However, plastic welding enables the creation of intricate and innovative car parts that were once unimaginable. This technology allows for complex geometric designs, integrated structures, and lightweight materials, all of which contribute to improved vehicle performance.

In the realm of car restoration and vehicle body repair, plastic welding has proven to be a game-changer. It facilitates the reproduction of original parts with precision, ensuring a seamless fit and maintaining the vehicle’s aesthetic appeal. Moreover, its application in vehicle dent repair ensures that damage can be efficiently minimized, preserving the integrity and value of the vehicle while offering cost-effective solutions compared to traditional metalworking methods.

Plastic welding technology plays a pivotal role in modern vehicle design and performance. By enhancing lightness, boosting durability, and offering unparalleled design flexibility, this innovative technique contributes significantly to creating more efficient, sustainable, and aesthetically advanced automobiles. As the automotive industry continues to evolve, embracing plastic welding technology will be key to staying at the forefront of vehicle innovation.