Plastic welding technology revolutionizes automotive collision repair with precise, durable bonds, reducing waste and costs. Essential for quick repairs, high-quality finishes, classic car restoration, and dent removal, it enhances structural integrity and cosmetic appeal while promoting environmental sustainability.

In today’s world, plastic welding technology is an indispensable skill for technicians seeking versatility and efficiency. This cutting-edge method transcends traditional joining techniques, offering a wide reach into diverse industries. Unlocking its potential allows for innovative repairs across various materials, from automotive to medical devices. This article delves into the transformative power of plastic welding, exploring its time and cost savings strategies, modern repair techniques, and the essential tools that empower technicians to excel in their craft.

- Unlocking Versatility: Plastic Welding's Reach

- Efficiency Gains: Time and Cost Savings Strategies

- Mastering Modern Repair: Techniques and Tools

Unlocking Versatility: Plastic Welding's Reach

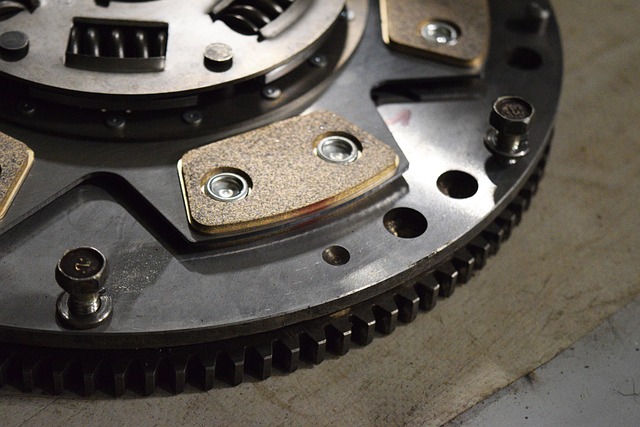

Plastic welding technology has unlocked a realm of versatility for technicians across various industries. Its application extends far beyond mere aesthetics; it’s a cornerstone in automotive collision repair, revolutionizing auto body services. From repairing cracked fenders to bonding complex composite parts, plastic welding offers precise solutions that enhance structural integrity and cosmetic appeal.

This innovative technology has become indispensable in the collision repair shop setting, where quick repairs and high-quality finishes are paramount. It empowers technicians to handle a wide array of materials, ensuring durability and longevity in every repair. In today’s world, where sustainability is paramount, plastic welding further contributes by reducing waste and promoting the reuse of materials, making it an eco-friendly choice for both industry professionals and consumers alike.

Efficiency Gains: Time and Cost Savings Strategies

Plastic welding technology offers significant efficiency gains for technicians across various industries, most notably in car collision repair and auto maintenance. By employing specialized equipment and techniques, such as robotic arm welding or hot gas welding, professionals can achieve precise, durable bonds that were once challenging with traditional methods. This not only speeds up the repair process but also reduces material waste, lowering costs for both technicians and their clients.

In a car body shop setting, efficient plastic welding streamlines operations, allowing for quicker turnaround times on repairs. This is crucial in meeting customer demands and maintaining high levels of service. Moreover, the ability to weld various types of plastics used in modern vehicles ensures that repairs are both functional and aesthetically pleasing, enhancing customer satisfaction in auto maintenance and collision repair services.

Mastering Modern Repair: Techniques and Tools

In the realm of modern automotive repair, plastic welding technology has emerged as an indispensable skill for technicians. This innovative approach transcends traditional methods, offering a nuanced and precise way to address repairs previously considered challenging or impossible. Technicians equipped with plastic welding expertise can now adeptly handle tasks such as car dent removal, ensuring seamless fusion of various plastic components found in modern vehicles.

The versatility of this technology extends beyond the confines of a regular car repair shop, proving invaluable in classic car restoration projects. Here, meticulous craftsmanship is paramount, and plastic welding enables restorers to preserve the original integrity of vehicles while addressing necessary repairs. This versatile skill set empowers technicians to navigate intricate labyrinths of plastic parts, ultimately enhancing the quality and longevity of their work, whether it’s a simple car dent removal or an elaborate classic car restoration.

Plastic welding technology has emerged as an indispensable skill for technicians, offering unparalleled versatility and efficiency gains. By mastering modern repair techniques and leveraging the right tools, professionals can significantly reduce repair times and costs while enhancing the durability of plastic components. As the demand for lightweight, durable materials continues to grow, a strong grasp of plastic welding is no longer a luxury—it’s a necessity in today’s advanced manufacturing landscape.