The auto industry witnesses a revolution in plastic welding technology, with ultrasonic and laser welding leading the charge for complex repairs of intricate parts. These advanced methods enhance repair quality, minimize material waste, and promote sustainability, setting new standards for collision centers. Robotic welding systems further revolutionize the process, offering precision, speed, and cost-effectiveness, transforming vehicle body shops and raising automotive craftsmanship to new heights.

The future of manufacturing is increasingly tied to advanced plastic welding technologies. As a versatile and efficient joining method, plastic welding is transforming industries from automotive to healthcare. This article delves into the latest innovations, exploring modern techniques like […], their diverse applications, and the safety considerations that ensure precise, high-quality welds. We also look ahead to emerging trends, analyzing their potential impact on shaping manufacturing processes globally.

- Understanding Advanced Plastic Welding Techniques

- – Exploring modern methods in plastic welding

- – Advantages and applications of new technologies

Understanding Advanced Plastic Welding Techniques

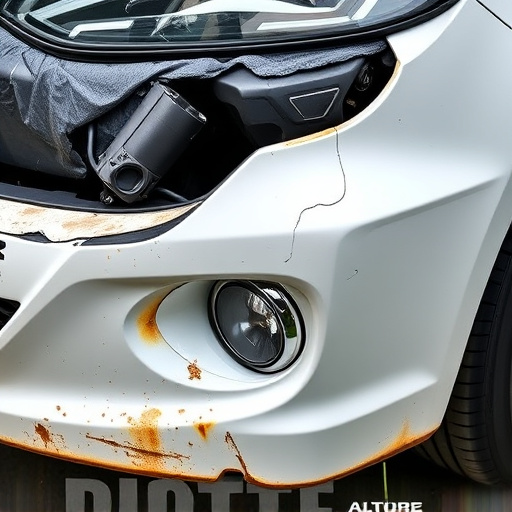

The world of plastic welding technology is constantly evolving, offering advanced techniques that were once unimaginable. Collision centers and collision repair services have embraced these innovations to provide state-of-the-art solutions for dent removal and complex repairs. One such technique gaining traction is ultrasonic welding, which employs high-frequency sound waves to melt and fuse plastics together. This method is particularly useful for intricate parts with narrow joints, ensuring precision and strength in the final welds.

Additionally, laser welding has revolutionized plastic welding technology. With its ability to deliver a highly focused beam of light, this technique provides exceptional control and accuracy during the fusion process. Collision repair professionals can now handle even the most delicate tasks, such as repairing auto body panels or complex electronic enclosures, with speed and efficiency. These advanced methods not only enhance the quality of repairs but also contribute to a more sustainable approach by minimizing material waste in the collision center environment.

– Exploring modern methods in plastic welding

The realm of plastic welding technology has seen a metamorphosis in recent years, with modern methods revolutionizing how we approach auto body repair and vehicle body repair processes, especially in collision repair centers. These innovative techniques have transformed the once complex and challenging task into a precise, efficient, and sustainable operation.

One notable advancement is the integration of advanced polymers and composite materials, which offer unparalleled strength and versatility. This shift has enabled more intricate designs and improved structural integrity in both auto body repair and vehicle body repair processes. Additionally, the adoption of robotic welding systems has enhanced precision and consistency, ensuring a seamless finish that was once difficult to achieve with traditional methods. These modern approaches not only streamline workflow but also contribute to reduced material waste, making them an environmentally friendly option for collision repair centers.

– Advantages and applications of new technologies

The advancements in plastic welding technology have brought about numerous benefits for various industries, particularly in the realm of automotive manufacturing and collision repair shops. These new technologies offer enhanced precision and efficiency, allowing for more complex and intricate welds on vehicle bodywork. For instance, laser welding has gained popularity due to its ability to create strong, precise joints with minimal heat input, ensuring better material retention and reduced warping or melting. This is especially advantageous in delicate areas of a vehicle body shop where traditional methods might not be feasible.

Additionally, robotic welding systems have revolutionized the speed and consistency of plastic welding processes. These automated systems can handle repetitive tasks accurately, improving productivity and reducing labor costs. In collision repair shops, this technology facilitates faster turnaround times for repairs, enhancing customer satisfaction. With its versatility, precision, and efficiency, modern plastic welding technology is transforming vehicle body shops, making them more equipped to handle complex repairs and fostering a new standard of quality in automotive craftsmanship.

As we’ve explored the advancements in plastic welding technology, it’s clear that these innovative techniques are transforming industries by offering precise, efficient, and sustainable solutions. From medical device manufacturing to automotive components, the applications are vast and growing. Continued research and development promise even greater capabilities in the future, making plastic welding an exciting and dynamic field to watch. Embrace these next steps to unlock new possibilities with this versatile technology.